ComIn I2105: New 5G LAN Solution

During the iterative upgrading process of intelligent manufacturing, the industrial network, as the core infrastructure, its flexibility, stability and efficiency directly determine the production efficiency. The traditional industrial wired network faces problems such as complex wiring, long renovation cycle and restricted equipment movement. "Line adjustment is accompanied by wiring reconstruction, and equipment migration causes network interruption" has become a key bottleneck restricting the flexible production of manufacturing enterprises. The emergence of 5G LAN technology breaks the physical constraints of traditional industrial networks. The ComIn I2105 industrial-grade 5G router, with its industrial-grade hardware configuration and native technology compatibility, becomes the core carrier for the implementation of 5G LAN technology in industrial scenarios, providing hard support for building an efficient, reliable and secure wireless communication system for smart factories.

5G LAN The technology is a new feature defined by 3GPP standards in the R16 phase. 5G LAN is a private mobile LAN service based on the access capabilities of 5G terminals and the 5G network. It enables enterprises to form "groups" for their terminals and provides flexible communication services such as terminal intercommunication or terminal isolation through the business server for the terminals within the group. Within the LAN, it can support point-to-point and point-to-multipoint communication modes based on IP or Ethernet.

1.1. Functional Scenario

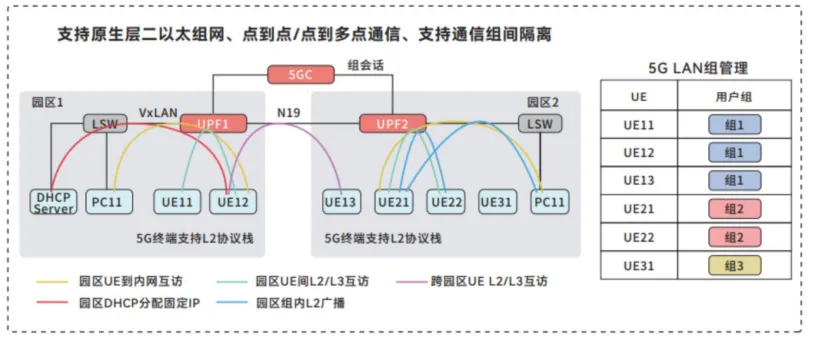

5G LAN Support for two-tier networking. After different UPFs implement 5G LAN networking, they can communicate directly with each other. The 5G LAN can achieve the following networking architecture:

Figure 1 :5G LAN Networking architecture

After completing the 5G LAN networking, the following functions can be achieved:

1.Two UEs under the same UPF can directly conduct Layer 2 interaction.

2.Different UPFs can interact directly through N19.

3.UEs that are not in the same 5G LAN user group cannot communicate with each other. As shown in the above figure, UE31 cannot access other 5G LAN user groups.

4.Enterprises can allocate IP addresses independently. As shown in the diagram of Park 1 above, enterprises can set up their own DHCP servers to allocate IP addresses.

The network setup is as follows:

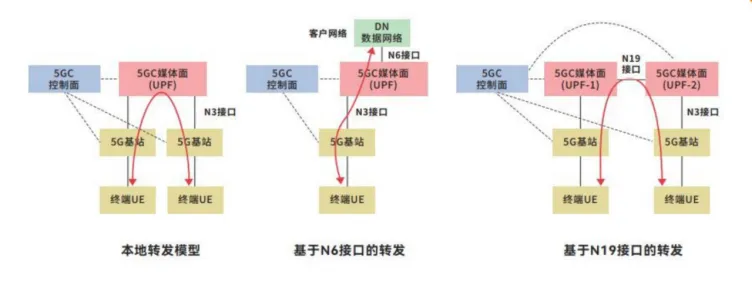

Figure 2 :Network side diagram

As can be seen from the above figure, two different UPFs can be connected through the N19 interface, and the UEs under these two UPFs can conduct layer 2 communication.

1.2. 5G LAN Advantages

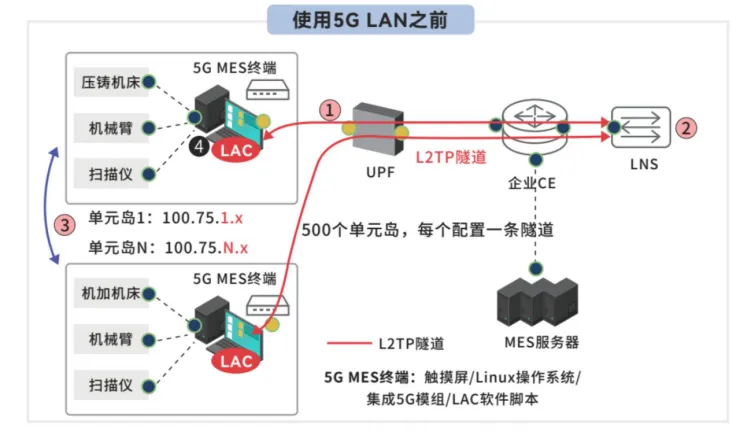

When 5G LAN is not used, different UEs dial using the default IP and then need to exchange data through the central server to achieve communication, resulting in high costs for network deployment and maintenance. The networking architecture without using 5G LAN is shown in the following figure:

Business pain points:

1.The adjustment of network data configuration involves a large amount of modification.

2.The network adjustment requires the terminal manufacturers to develop compatible solutions.

3.The network adjustment requires the collaboration of terminals, applications and enterprises, and the deployment is very difficult.

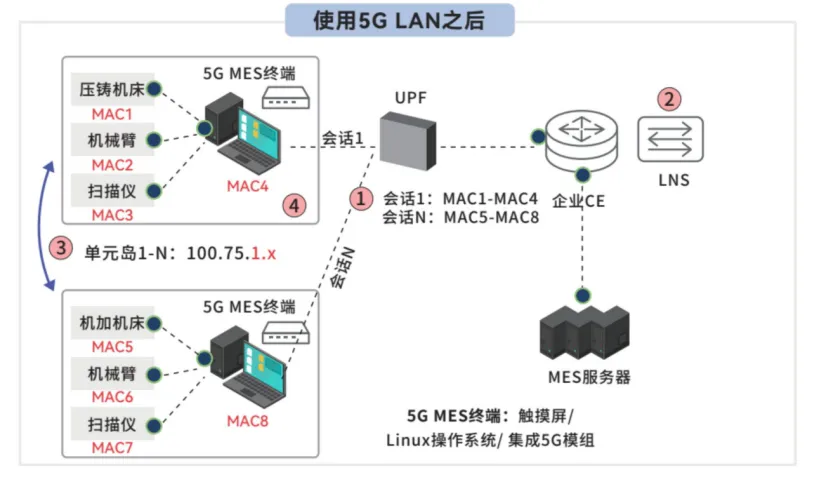

When using 5G LAN, different UE terminals can directly conduct Layer 2 data exchange without the need to deploy enterprise CE.

The networking architecture when using 5G LAN is shown in the following figure:

Figure 4: Network Architecture when Using 5G LAN

The advantages of using 5G LAN are as follows:

1. In the industrial internet, the cost of network construction can be reduced without the need to set up additional tunnel equipment.

2. Supports two-layer networking, and can use industrial protocol messages;

3. Reduce latency and network load.

The ComIn I2105 industrial-grade 5G router is designed according to industrial standards, deeply adapting to the technical characteristics of 5G LAN. From the hardware configuration to the functional design, it fully meets the strict requirements of industrial scenarios, establishing a communication guarantee system that is "stable and reliable, interface compatible, secure and controllable, and operation efficient".

The equipment adopts a full-metal casing design, featuring excellent electromagnetic interference shielding performance. Its operating temperature range is from -35℃ to 75℃, and the storage temperature can be as low as -40℃. It is suitable for complex industrial environments such as high-temperature welding workshops and low-temperature storage areas. It supports dual network systems of 5G NR-SA (3GPP R17 Redcap) and 4G LTE, and can be combined with wired networks to form a dual-link intelligent hot backup mechanism. It supports the hardware watchdog fault automatic repair function to ensure zero network interruption in key scenarios such as AGV scheduling and real-time control. It is equipped with 2 standard SMA antenna interfaces and a high-sensitivity external antenna, fully compatible with mainstream 5G frequency bands, achieving seamless signal coverage in the workshop.

The interface configuration takes into account the diverse requirements of industrial equipment, equipped with 1 gigabit WAN port and 1 gigabit LAN port, both of which are internally equipped with 1.5KV electromagnetic isolation protection to ensure stable connection of high-definition cameras, PLC controllers and other devices. Through industrial phoenix terminals, RS232/RS485 serial ports are provided, fully compatible with industrial protocols such as Modbus and MQTT, enabling seamless integration of old instruments and sensors. It supports 2.4GHz WiFi (802.11n protocol, maximum rate 300Mbps), meeting the access requirements of mobile terminals for on-site operation and maintenance, and constructing a full-dimensional device connection matrix.

3. Full-chain security protection, building a solid barrier for industrial data securityAt the hardware level, the SIM card interface is equipped with 15KV ESD protection, and the power interface is equipped with reverse protection and overvoltage protection mechanisms, providing physical protection against external security risks. At the software level, it supports multiple protocols such as PPTP/L2TP/OpenVPN/IPSec for VPN encrypted transmission. Combined with the MAC address filtering function, it enables full encryption transmission of production data and precise control of access devices, eliminating the risks of data leakage and malicious device access.

The deep integration of ComIn I2105 with 5G LAN technology has achieved large-scale application in multiple industrial scenarios. Through technological innovation, it has solved production problems and enhanced production efficiency and economic benefits.

1. Precision manufacturing AI quality inspection: Millisecond response enhances detection accuracy

In the AI visual quality inspection scenario of lithium battery manufacturing enterprises, the ComIn I2105 connects to the 5G LAN network through the 5G SA mode, enabling real-time transmission of high-definition image data with a transmission delay controlled within 10ms. Combined with the local data processing capabilities of the equipment, the defect recognition accuracy rate has increased from 95% to 99.3%, the rejection rate of non-conforming products has risen by 80%, and the annual reduction in rework losses exceeds 2 million yuan, providing technical support for the quality control of precision manufacturing.

2. Flexible production of automotive components: Rapid networking accelerates production line iterations

In response to the urgent demand for new energy vehicle orders, automotive component manufacturers have leveraged the rapid networking capabilities of ComIn I2105 to efficiently transform their traditional production lines into motor accessory production lines. The newly deployed robots and automated equipment directly connect to the existing system via 5G LAN. The old stamping equipment synchronously connects to the network through the RS485 serial port, and in combination with the cloud platform for remote parameter configuration, the production line adjustment time has been shortened from 3 days to 8 hours, and the order delivery cycle has been reduced by 40%, significantly enhancing the enterprise's flexible production response capability.

3. Warehouse Logistics AGV Collaborative Scheduling: Precisely Synchronizing to Enhance Logistics Efficiency

In the storage area of the electronic factory, 10 AGV vehicles are deployed for material distribution. They are connected to the 5G LAN network via ComIn I2105 and utilize the native multicast function of the technology to achieve synchronous distribution of scheduling instructions. The positions, battery levels, and other data of the AGV vehicles are transmitted back in real time through the 5G network. The response time for path planning has been reduced from 1.2 seconds to 0.3 seconds, improving the material distribution efficiency by 50% and the warehouse turnover rate by 30%. This solution addresses the scheduling chaos caused by traditional network instruction delays and lagging status feedback.

4. Intelligent Monitoring in Metal Smelting Plants: Eliminating Wiring for Enhanced Safety Control

Due to the large span and extensive coverage area of each factory in the metal smelting plant, the traditional wired monitoring wiring faces the problems of "high excavation difficulty, cable corrosion and breakage, and the need to re-wire when equipment is moved". Based on the ComIn I2105 and 5G LAN solution, the "power is available then deployment" is achieved: 4K high-definition industrial cameras are deployed in industrial parks, raw material warehouses, and workshops. Through ComIn I2105, they are directly connected to the 5G LAN virtual domain, and the monitoring video is transmitted in real time to the core network video server. The video transmission delay is less than 15ms, the deployment cycle is shortened by 90% compared to the traditional solution, and the later adjustment of the position only requires modifying the power lines to complete.

With the continuous advancement of 5G R17 and R18 standards, 5G LAN technology will further enhance its integration capabilities with edge computing, artificial intelligence, and industrial internet, achieving lower latency, higher reliability, and more flexible networking capabilities. ComIn I2105, as the core carrier for technology implementation, its modular design and sufficient hardware redundancy will fully adapt to the technical upgrade requirements of future industrial scenarios, promoting the deep transformation of industrial networks from "passive operation" to "active control", and from "wired constraints" to "wireless freedom".

In the context of the accelerated penetration of intelligent manufacturing, 5G LAN technology is reshaping the underlying communication logic of industrial production. The ComIn I2105 industrial-grade 5G router, with its industrial-grade stable performance, full-scenario adaptability and security and reliability features, provides a high-starting-point and low-barrier wireless communication solution for the digital transformation of manufacturing enterprises. From production line upgrades to equipment networking, from data control to intelligent operation and maintenance, the ComIn I2105 is becoming the core bridge connecting technology and production, helping manufacturing enterprises build an efficient, intelligent and flexible production system and embarking on a new journey of intelligent manufacturing.

If you are having trouble setting up a network for your factory, you might want to consider the 5G LAN solution. The ComIn I2105 might be able to help you address the issues and reduce costs.

If you need any assistance, please feel free to leave a message through the backend to request that we prepare a detailed technical parameter table for ComIn I2105 that is compatible with 5G LAN. This will help you compare the compatibility with your existing equipment!